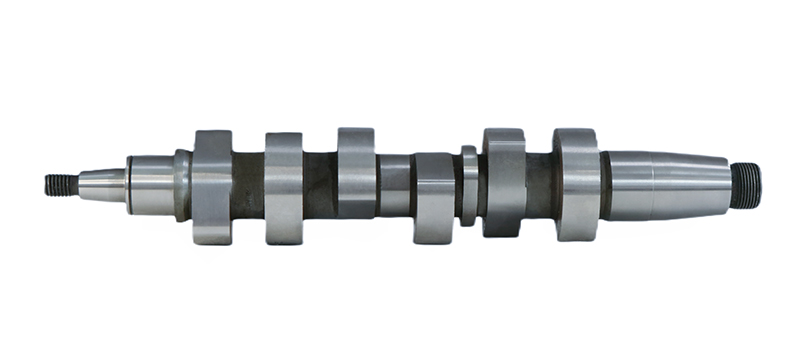

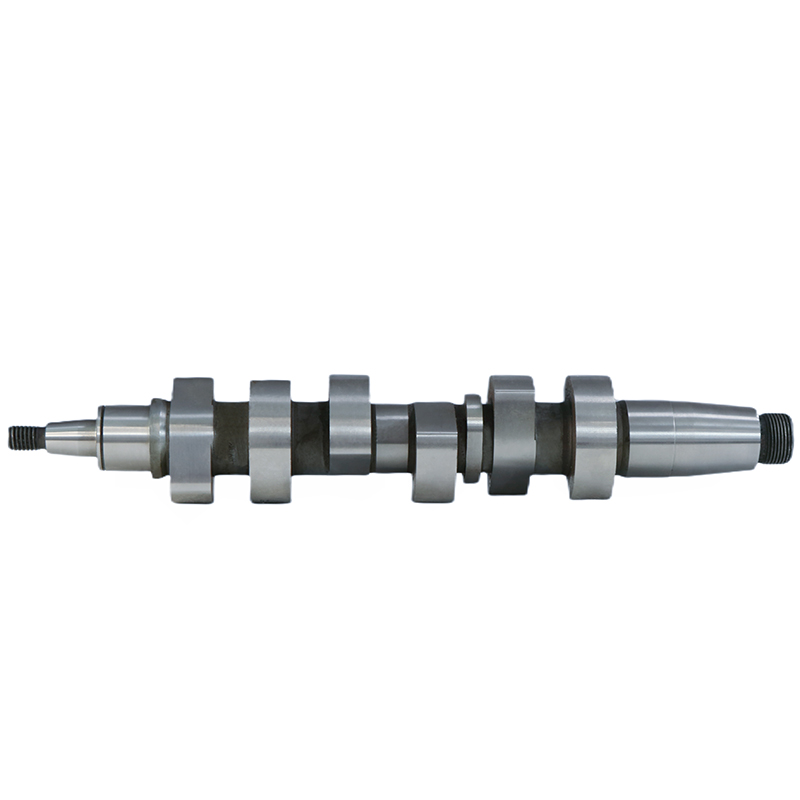

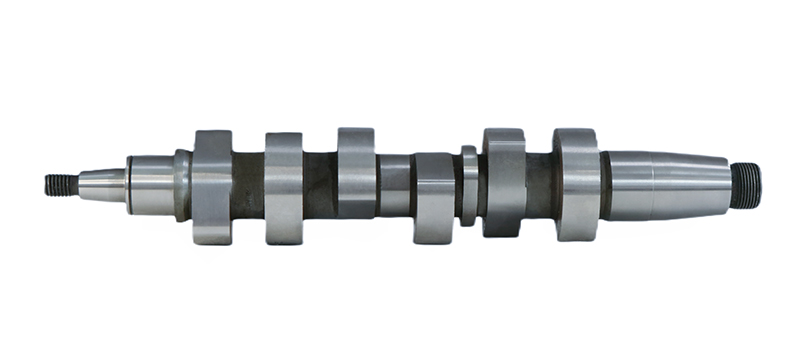

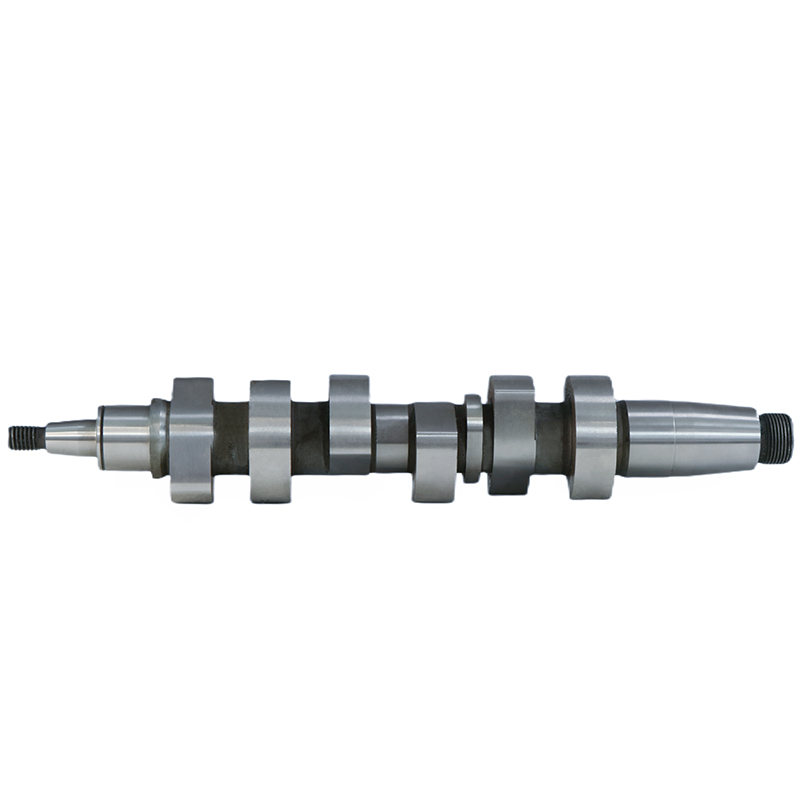

Best Quality Direct Injection Pump - Fuel Injection Pump 8500 Series Camshaft Model No.168-0201-5YDM – Weikun

Best Quality Direct Injection Pump - Fuel Injection Pump 8500 Series Camshaft Model No.168-0201-5YDM – Weikun Detail:

Advantages

● Good wear resistance and precise size.

● Conducive to smooth engine operation.

● High quality material and long service life.

Description

Fuel pump camshaft is a part of a piston engine. Its function is to control the valve opening and closing action. Although the camshaft in a four-STROKE engine can rotate at half the speed of the crankshaft, its speed is still very high. Therefore, the camshaft design in the strength and support of the requirements are very high. Its material is generally high quality alloy steel or alloy steel. The design of camshaft plays a very important role in engine design because the rule of valve movement is related to the power and operation characteristics of an engine.

The main body of the camshaft is a cylindrical rod of approximately the same length as the cylinder. It is covered with a number of cams for driving the valve. Camshaft is supported in camshaft bearing hole by camshaft journal, so the number of camshaft journal is an important factor affecting the stiffness of camshaft support. If the camshaft stiffness is insufficient, bending deformation will occur during work, which will affect the timing of valve.

The sides of the camshaft are egg-shaped. It is designed to ensure adequate intake and exhaust of the cylinder. In addition, considering the durability of the engine and the smoothness of operation, the valve can not cause too much impact due to the acceleration and deceleration process in the opening and closing action. Otherwise, it will cause serious valve wear, increased noise or other serious consequences.

Features

The camshaft is subjected to periodic impact loads. The contact stress between camshaft and tappet is very high, and the relative sliding speed is also very high. Plus, the wear of camshaft working surface is more serious., On one hand there will be high dimensional accuracy, small surface roughness and enough stiffness existed on the camshaft journal and CAM working surface, on another hand, there will also be high wear resistance and good lubrication existed. Moreover, camshafts are usually forged from high quality carbon steel or alloy steel, and it can also be casted from alloy or ductile iron.

Product detail pictures:

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Best Quality Direct Injection Pump - Fuel Injection Pump 8500 Series Camshaft Model No.168-0201-5YDM – Weikun , The product will supply to all over the world, such as: Kenya, Angola, Bulgaria, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we are going to continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.